Photo: Michael Schwarzenberger

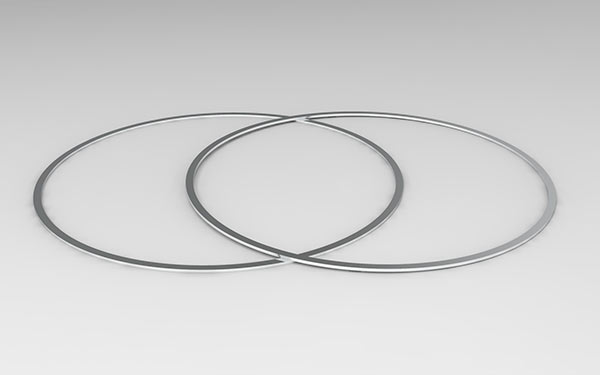

Butterfly valves are used to control air flow in bleed air systems and for environmental control systems. A typical butterfly valve includes a housing that defines an air flow passage. A shaft is mounted in a housing and supports a butterfly disk that incorporate a sealing ring and a stiffer. An actuator rotates the shaft to selectively open or close the butterfly disk to control the air flow through the passage in the housing. In this type of configuration, leakage is generated mainly by the wear of the sealing elements. Thus, the wear rate is the main parameter to be considered, and the well understanding of the high temperature wear behaviour of the materials used in these components under extreme conditions is essential.

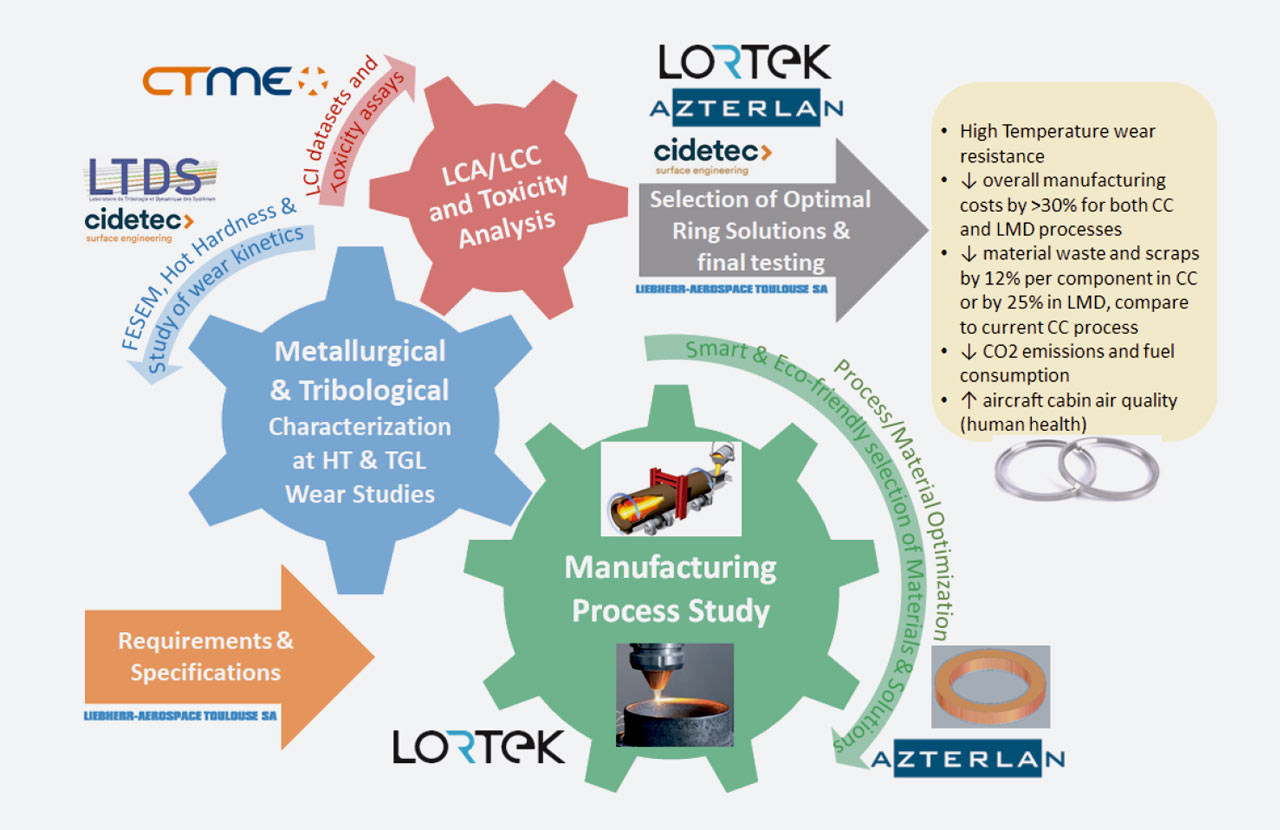

Nowadays, cobalt alloy like Stellite 6 is used for the manufacturing of the butterfly sealing rings. High temperature wear of sealing rings and stiffness under complex thermomechanical stresses leads to bleed valve internal leakage increase. The limitation of leakage through the correct selection of materials, the design of the sealing rings and housings, adequate manufacturing routes and the correct assembly between the stiffener and the butterfly will ensure a perfect seal avoiding possible leaks during operation, what will lead to a reduction of fuel consumption of about 1.8 kg/h for small-medium range aircraft. Furthermore, the avoidance of cobalt oxidized wear particles in the airflow will result on an improved cabin air quality.

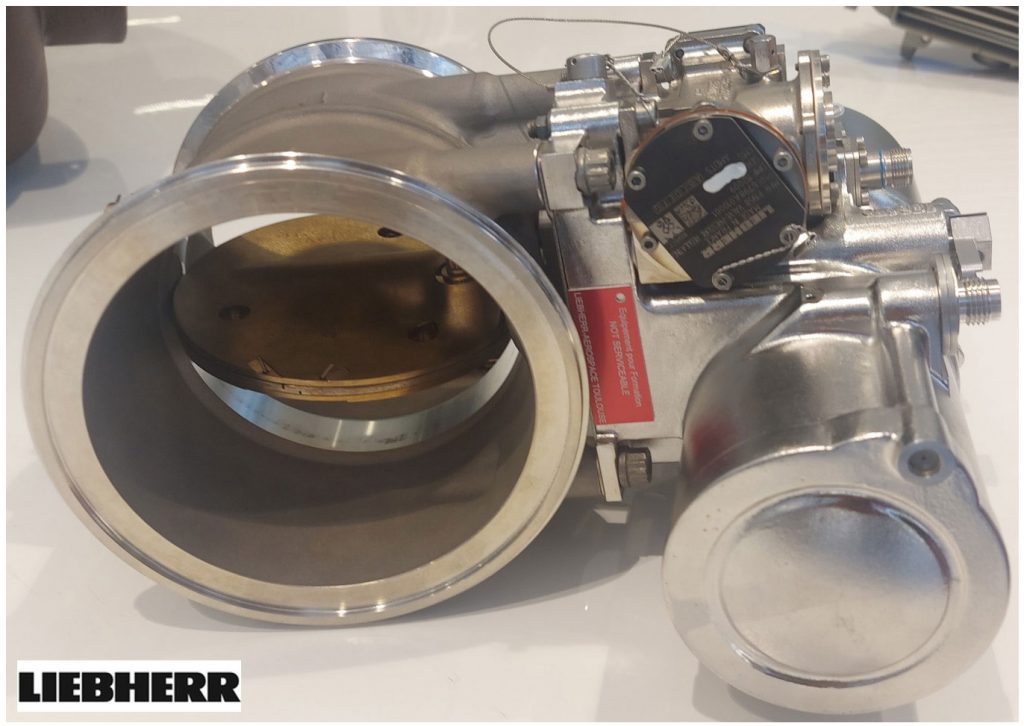

Photo: Courtesy of Liebherr

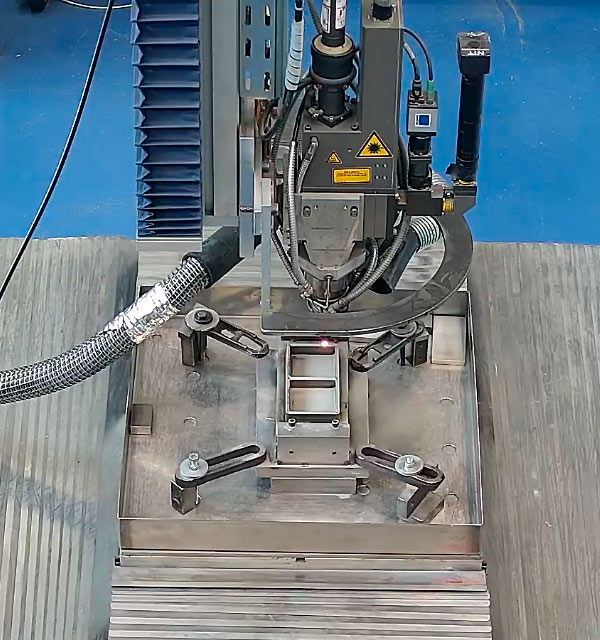

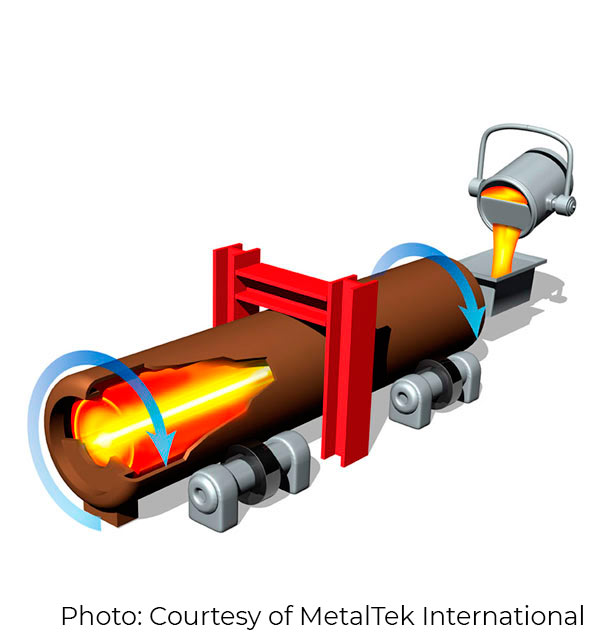

Nickel-based alloys like NiCrSiFeB Self-Fluxing alloys exhibit excellent corrosion and are reported to be wear-resistance up to 600 oC. They also demonstrate an excellent oxidation resistance up to melting range, and satisfactory resistance to some organic acids. Nowadays, these materials are mainly used as coatings. So, the project will identify and define the critical process parameters to manufacture the Nickel based self-fluxing alloys by Centrifugal Casting (CC) and Laser Metal Deposition (LMD).

New manufacturing routes for Ni Based self-fluxing alloys

It will be possible to manufacture bulk parts of NiCrSiFeB alloys. Control of solidification ranges to avoid microshrinkage problems will be key in CC process, together with process modelling to reduce setting up times. Specific process conditions such as thermal gradients and fine powder stream will be combined with a melt- pool size monitoring system and a multivariate process control system in LMD process. The development of robust manufacturing study will be supported by advanced data analytics.

How to determine the best NiCrSiFeB alloy as Cobalt alloy replacement

- Extensive tribological studies at high temperature

- High temperature mechanical properties (hot hardness) Advanced Microstructural analysis

- Toxicity analysis

- LCA & LCC analysis

Demonstrators

Firstly, the best combination of process parameters for both CC and LMD and chemical composition will be selected. Afterwards, 8 sealing rings will be manufactured, 4 by CC and 4 by LMD, including post-processing operations for endurance test. A complete characterization of the worn surfaces of the tested rings

will be carried out by electron microscopy and non-destructive testing. These results together with outcomes from toxicity analysis and LCA/LCC will define the potential substitution of current Cobalt rings by the developed alternative ones.

- To reduce the overall manufacturing cost of sealing rings >30% for both CC and LMD process maintaining or increasing the wear resistance as compared to Stellite 6.

- For LMD process, to reduce time- to-market from several months to one month.

- To obtain viable solutions to replace Cobalt in future aero components.

- Reduce EU dependence on critical raw materials like Cobalt.

- To reduce material waste and scraps by 12% per component for CC and 25% per component for LMD.

- To reduce CO2 emissions, perceived noise and fuel consumption due to the expected limitation of leakage and the suppression of pressure relief holes per valve leading to a reduction of fuel consumption of 1.8 kg/h for small-medium range aircraft.

- To contribute to the development of next generation of High Performance and Energy Efficient systems, such as for new Environmental Control Systems (ECS) to be incorporated in the Ultra High By-pass Ratio (UHBR) engine of future aircraft.

- To improve aircraft cabin air reducing the potentially contaminated bleed air.

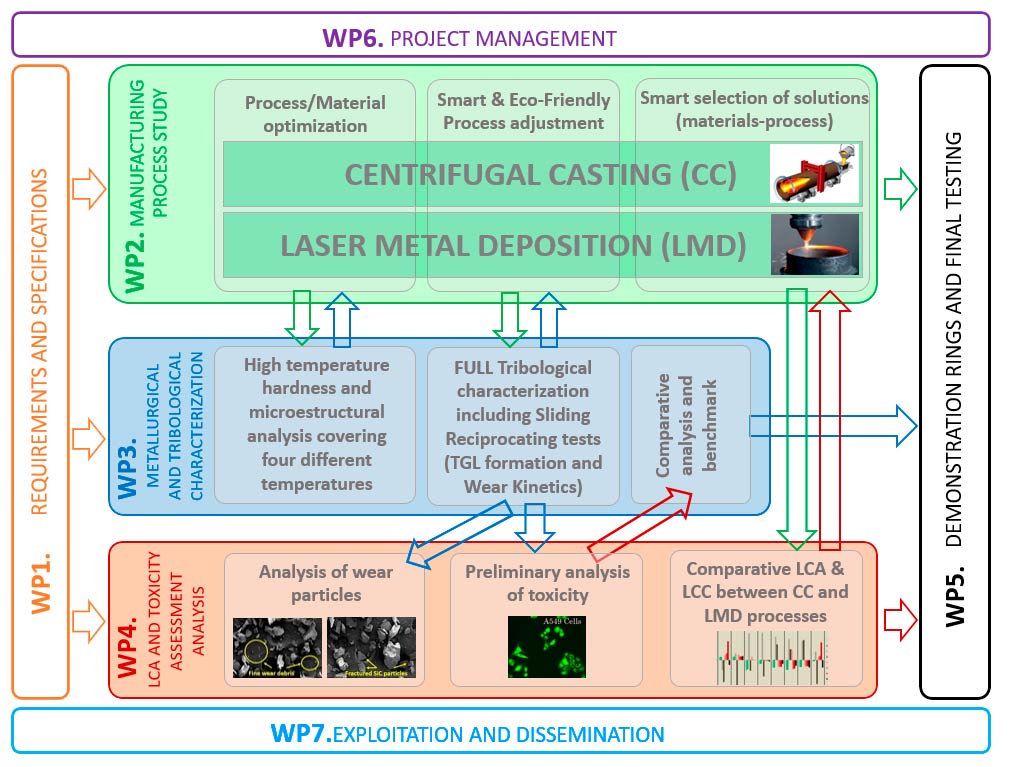

The work plan is divided into 7 WPs – 2cross-cutting WPs (dedicated

to Project Management and to Dissemination and Exploitation), and 5 technical WPs – with a duration of 24 months (from 1st January 2021 to 31st December 2022).

- WP1 is dedicated to the definition of the requirements and specifications for the sealing rings, study of the self-fluxing nickel alloys to be used and definition of the test plan.

- WP2 will address the manufacturing process study, including the obtaining of the best parameters to manufacture NiCrSiFeB alloys by both CC and LMD together with the use of advance data analytics methodologies.

- WP3 will be focused on the metallurgical and tribological characterization of the best candidates selected in the previous WP. Wear rate evolution of the selected Ni-alloys will be compared to Stellite 6.

- WP4 will be focused on environmental aspects. Thus, wear particles will be analysed and the toxicity of debris particles will be assessed. Additionally, the environmental impact and life cycle cost of the sealing rings obtained by CC and LMD will be obtained and compared to current product.

- After selecting the most promising Ni-alloy solutions for both processes, WP5 will address the manufacturing of the sealing rings and their final testing.

MAIN CONCLUSIONS

AND ACHIEVEMENTS

After finalizing the execution of WP2 and WP5 tasks, the main progress was done on the final selection of the 2 most promising composition grades for self-fluxing nickel alloys, and the manufacturing of the tubes preforms by gravity casting (GC) and Laser Metal Deposition (LMD) processes. Finally, two sets of sealing rings prototypes were machined, grinded and tested at Liebherr up to 20 000 cycles and the leakage measured, evaluated and compared against current solutions of materials used for the sealing rings.

Other major progress was the completion in WP3 of the tribology studies at room and high temperature (up to 650 °C) for the NiCrSiFeB alloys obtained by the two new manufacturing routes proposed in NEMARCO (GC and LMD). High load tests were conducted to generate the debris particles for the preliminary toxicity analysis conducted in WP4. The wear kinetics study at variable contact temperature was completed. The main conclusions after tribological characterization and studies conducted in NiCrSiFeB alloys and Stellite 6 reference alloy were stated, determining the wear mechanics, wear response, and the mechanisms of the glaze layer formation in NiCrSiFeB alloys. A new methodology to characterize the tribological behaviour under high temperatures using a limited number of tests and samples were created by ECL-LTDS.

In WP4, preliminary analysis of wear particles toxicity study was made, observed effects are comparable between the wear particles obtained from NiCrSiFeB samples researched in the project and those from the Stellite 6 controls. An extensive LCIA study were made after finalizing WP2 and WP3 activities, and after the tubes preform manufacturing in WP5. The main findings were compiled. The LMD process is cheaper than GC manufacturing route for sealing rings prototypes obtained at lab scale. The comparative CO2 emissions between the current industrial manufacturing route (with Stellite 6 and CC process) and the proposed new manufacturing routes (GC and LMD) is biased since in NEMARCO project the measured values and recorded data has been extracted in pilot lab scale processes, not fully representative of a serial industrial production environment. According to the environmental study conducted, CO2 emissions in the best-case scenario for the LMD manufacturing route of NiCrSiFeB sealing rings are higher than GC manufacturing route developed.

After endurance tests conducted by Liebherr, the leakage measurements show the good behaviour of the developed materials in NEMARCO. The alloy obtained by LMD route seems more sensitive to wear especially on external face of the sealing rings. The materials obtained by GC and LMD exhibits some brittle defects that should be avoid working on the design and the manufacturing process that still need to be better adapted to NiCrSiFeB composition grades selected. The final results are very interesting and promising.

NEMARCO project is composed of 5 partners from 2 different countries (Spain and France), with complementary skills and experience, covering the whole project value chain. The partners are referent entities in their fields at European level and have collaborated together in previous projects.

LORTEK is the project coordinator. LORTEK and AZTERLAN will be focused on manufacturing, specifically the former on LMD and the later on CC, both for the process study as well as the manufacturing of the demonstration rings. CIDETEC and LTDS will deal with the metallurgical and tribological characterization, while CTME will address the toxicity assessment and the life cycle cost analysis. LORTEK will be responsible of exploitation and dissemination.